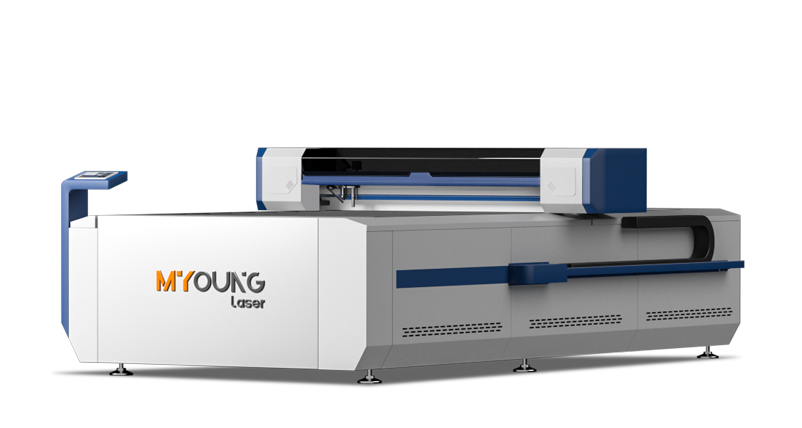

Industrial Grade Equipment

That Creates Higher Quality

Acrylic Work

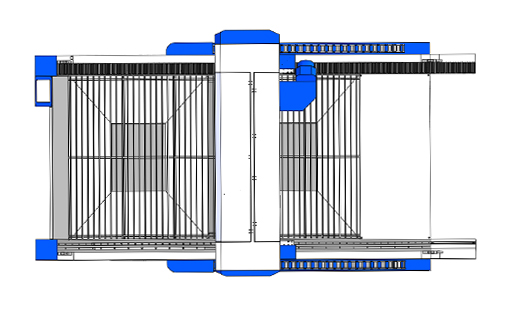

LARGE SIZE LASER BED

Laser Cutting Bed

M1325/1350

The quality of acrylic cutting heavily depends on the equipment used. High-specification machines not only offer greater precision but also ensure perfect cutting edges. Key inspection criteria include smooth end faces, no bubbles, rounded corners, and good taper.

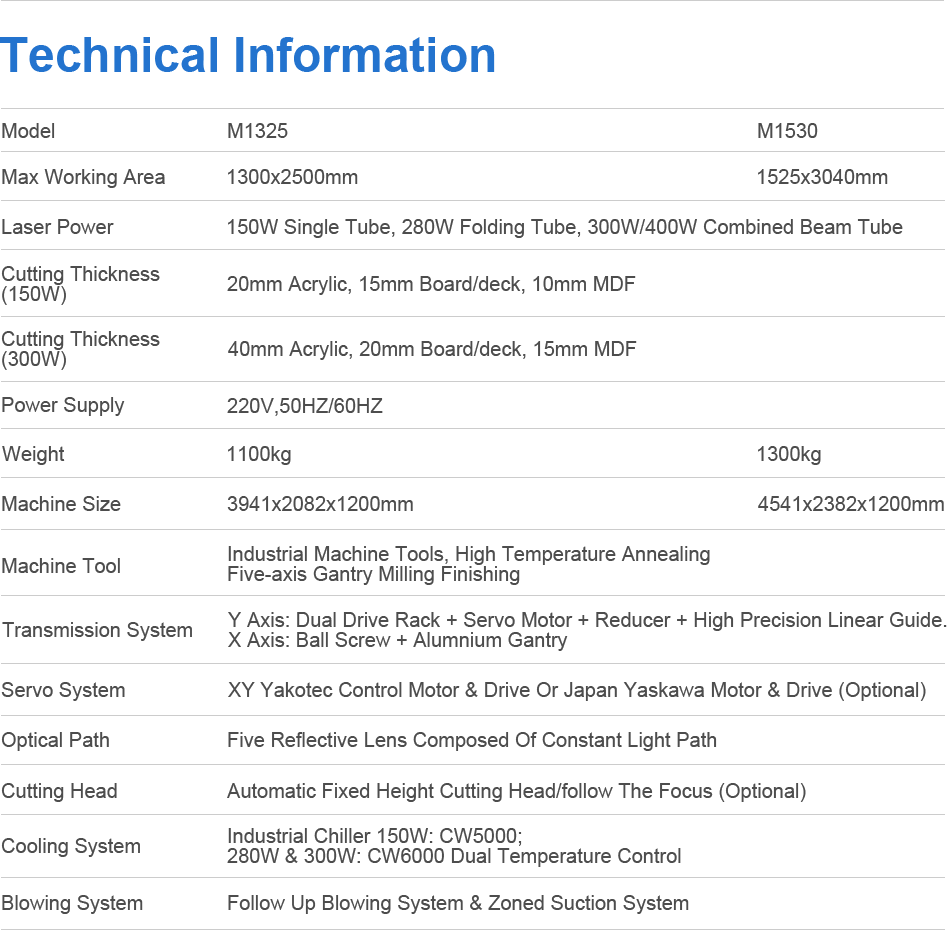

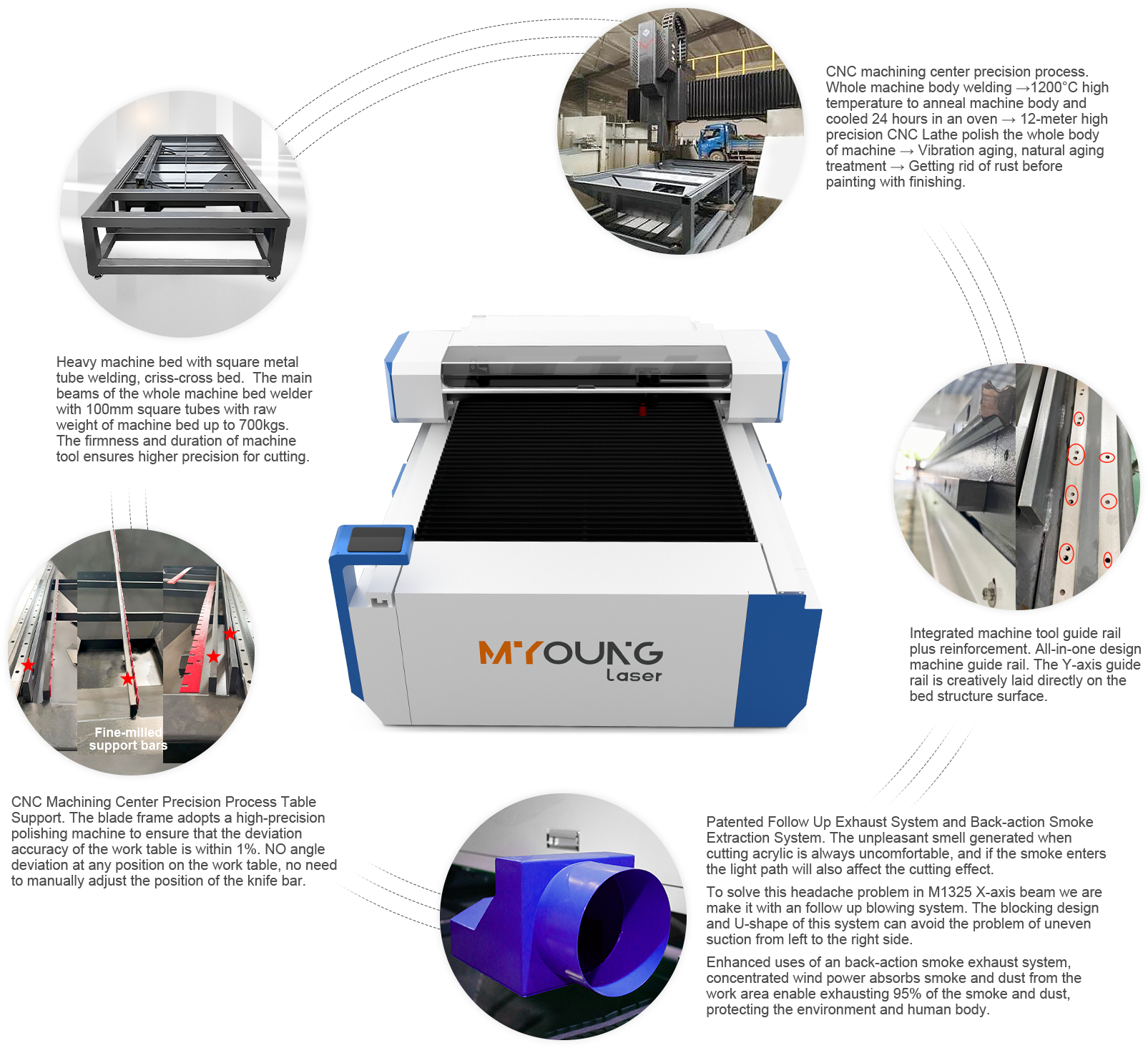

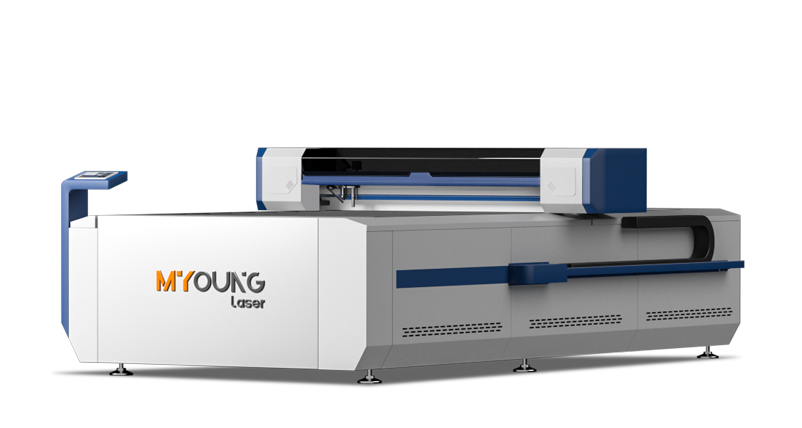

A well-designed machine with optimal mechanical structure is essential for improving the accuracy and quality of acrylic cutting. Myoung Laser’s M1325 and M1530 models embody this principle perfectly. Built to industrial-grade standards, these models use a Rack & Pinion structure with a speed reducer and servo motor. This design optimizes the optical path, ensuring consistent laser beam energy and significantly enhancing the thickness and quality of acrylic cutting.

We believe only a professional machine can create the best work. If you agree, the M1325 and M1530 industrial-grade series are your top choices for acrylic cutting.

Features Of Our Products

Easy To Maintain

Strong & Durable Machine Bed

User-Friendly Operation

High Precision Transmission System

Revolution Of Machine

Bed – Stability

Transmission

Innovation – Efficient

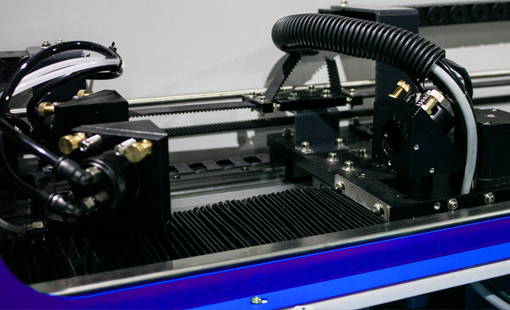

High-Precision Dual Drive Transmission System

The dual drive rack & pinion with a speed reducer and guide rail system provides high load capacity and 0.1mm transmission accuracy. This ensures precise transmission and allows speeds up to 2m/s.

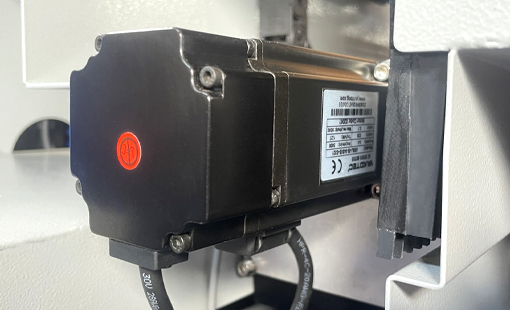

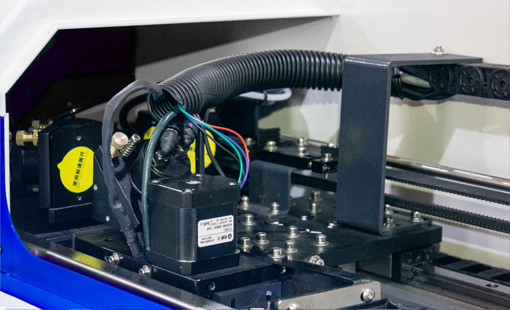

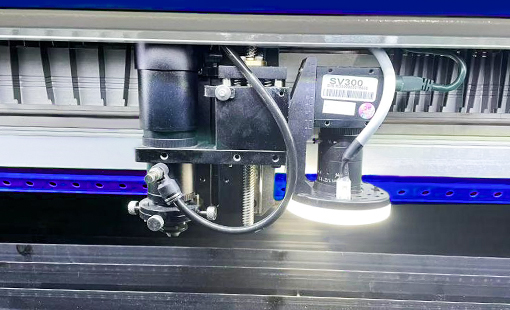

Servo Motor

Servo motors enhance machine precision and speed with their high integration, compact size, full protection, and reliability. Advanced space vector control algorithms ensure accurate and fast operations.

Water-Cooled Light Path

The water-cooled light path precisely controls laser emission direction, reduces thermal distortion of mirrors, and improves beam quality.

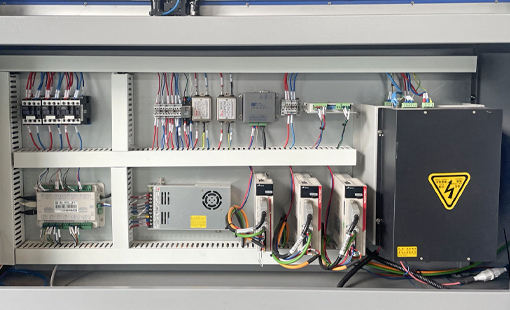

High-Quality Switch Power Cabinet

The cabinet design uses high-quality buttons and switch power, ensuring a premium appearance and performance. Each line is clearly marked for quick and easy port identification.

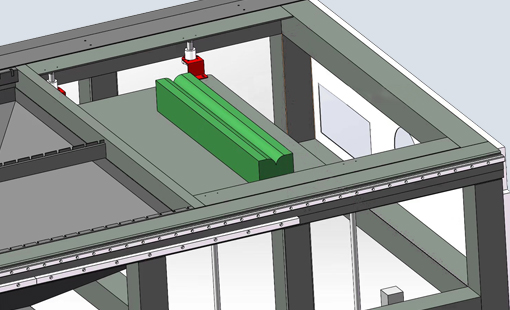

Ball Screw System

The X-axis features a high-precision ball screw structure with a double guide rail and servo motor. This system ensures high transmission efficiency, longevity, minimal maintenance, and is ideal for high-speed operations.

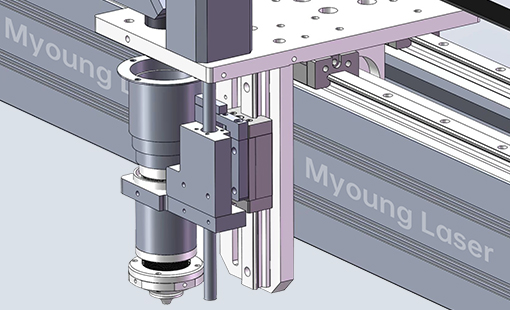

Constant Optical Path Compensation Device

The X-axis features a constant optical path compensation device to maintain consistent laser beam and energy from the first reflector to the focusing mirror. This ensures stable, high-quality cutting by keeping the laser beam’s power and focus spot consistent, overcoming divergence issues.

Built-In Auto-Focus Cutting Head

The auto-focus cutting head automatically adjusts focus between the material and cutting head, simplifying operation and ensuring precise cutting.

Heat Exchanger

The heat exchanger keeps the electrical components in the cabinet cool, reducing dust buildup and extending their lifespan for three to five years by maintaining a low temperature.

Aerospace Extruded Aluminum Beam

The industrial aerospace extruded aluminum beam is lightweight, low density, highly tough, and corrosion-resistant. These features ensure fast speeds and excellent dynamics for the machine.

Fully Sealed Design

The fully sealed design reduces maintenance by preventing dust and smoke from entering the light path. A dust cover minimizes pollution, maintaining optimal reflectivity for high-quality acrylic cutting.

High-Quality Laser Tubes

We provide stable, high-quality laser tubes in 150W, 280W, 300W, and 400W, with options from brands like RECI, YongLi, Joy Laser, and ECO2, to suit various material thicknesses.

Automatic Refueling System

The automatic refueling system, with an auto-oil dropper and oil-water separator, helps reduce internal rusting.

Optional Configuration

Edge-Seeking Camera (RUIDA)

The Edge-Seeking Camera (RUIDA) supports mark point visual cutting, shaped matching cutting, and projection cutting. It’s ideal for rapid cutting in industries like garment leather, digital printing, and advertising, suitable for trademarks, textile embroidery, and clothing fabric.

Customized Rotating Shaft

OEM Solutions

OEM solutions cater to the higher demands of high-end customers.

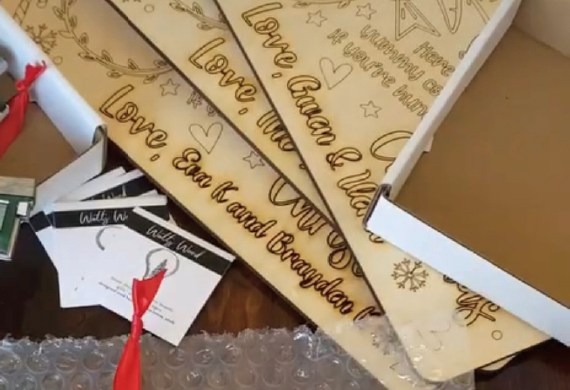

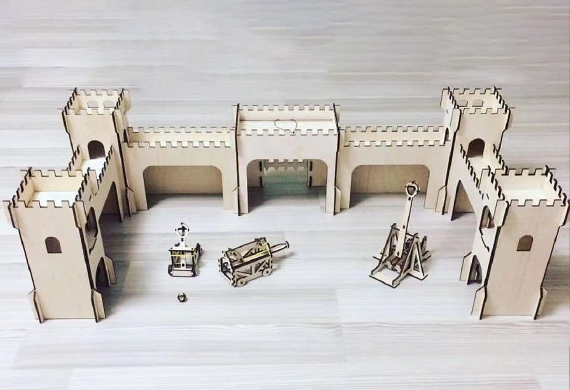

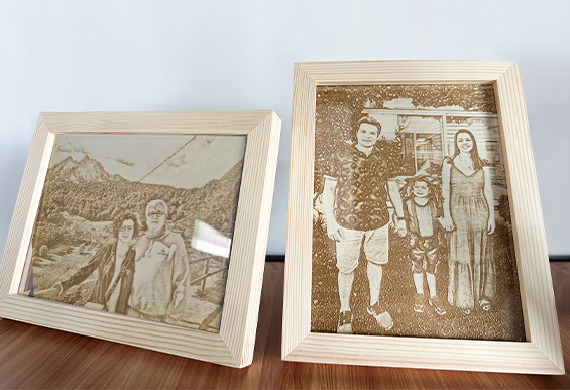

Bring You Imaginations

Into Life