Innovative Acrylic Laser Cutting Projects – Profitable Ideas with Dura Series

INDUSTRIAL NEWS

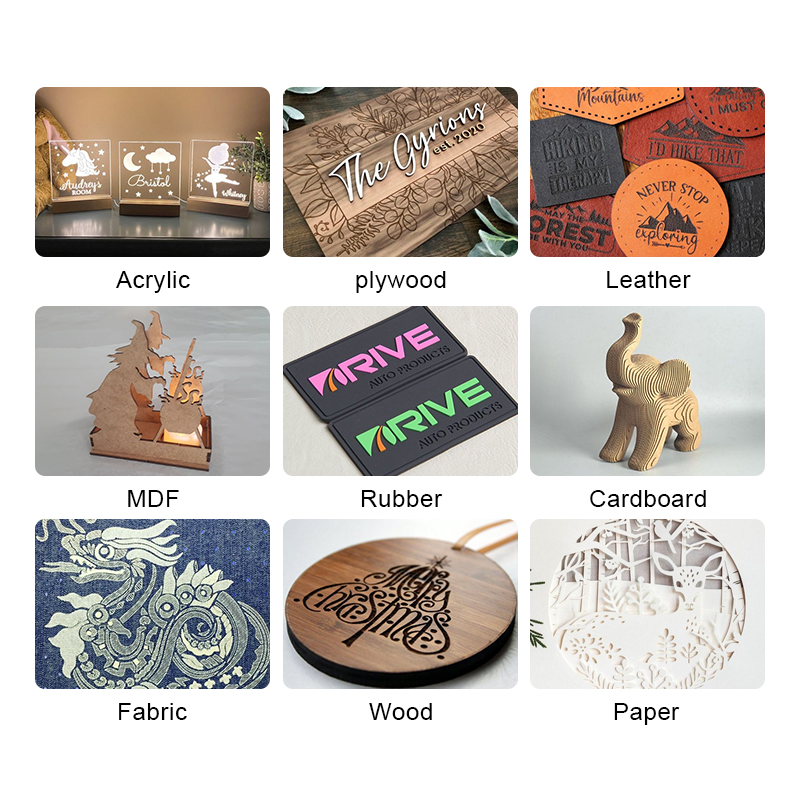

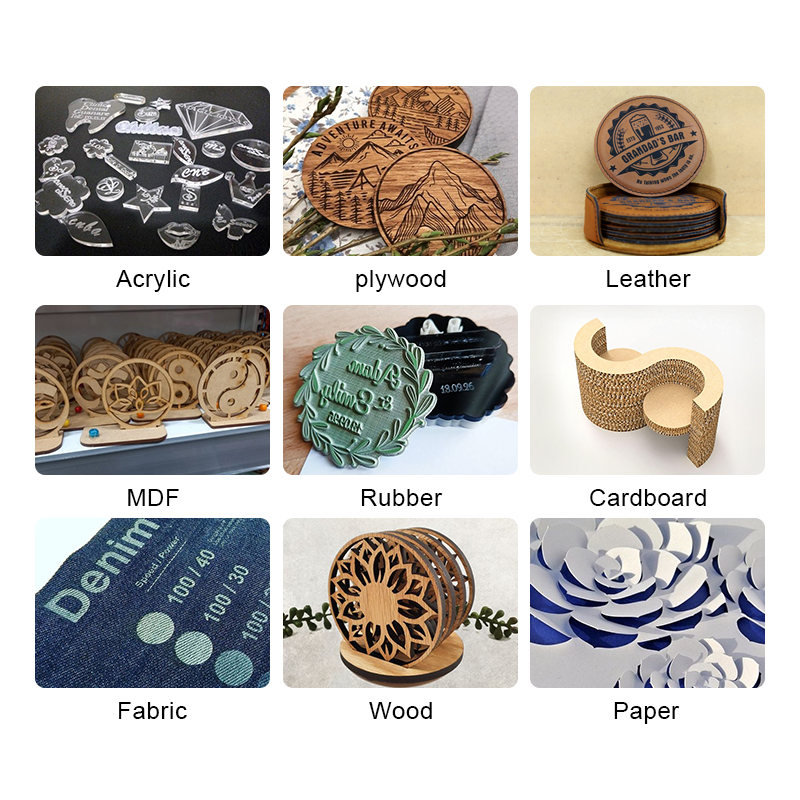

In recent years, acrylic has become one of the most popular materials for creative projects due to its versatility, durability, and transparency. With the rise of CO2 laser cutting machines, many of our clients have leveraged these machines to create stunning, profitable acrylic products that cater to both personal and commercial markets.

Many of our customers have used the Dura Series CO2 laser machines to design and produce a wide range of acrylic crafts. These products, ranging from home décor and personalized signage to custom jewelry and awards, are high in demand and offer substantial profit margins. Here are a few popular projects:

- Custom Acrylic Signs: Perfect for businesses, weddings, and events. These signs are precise, customizable, and add a professional touch.

- Acrylic Jewelry: Laser cutting allows for intricate designs, turning simple sheets into high-quality, elegant pieces.

- Home Décor: From wall art to furniture accents, laser-cut acrylic provides endless possibilities for interior design enthusiasts.

- Keychains and Personalized Gifts: Smaller items like keychains are quick to produce and offer high returns due to personalization.

The success of our customers shows that with the right tools, even small-scale operations can generate significant profits by tapping into the growing demand for acrylic products.

The Dura Series CO2 laser cutting machines are an ideal solution for businesses and hobbyists working with acrylic. Our machines come with features that ensure precision, speed, and high-quality results, making them a top choice for creative entrepreneurs. Here’s why:

- Fast and Quiet Operations: Equipped with linear module guide rails, our machines ensure smooth, efficient, and silent performance, even at high speeds.

- High Precision with Japan Shinano Motors: The high torque and precision offered by these motors ensure that your designs are accurate, regardless of complexity.

- Durable and High-Performance Components: We use only top-quality laser tubes, power supplies, and water chillers to ensure the longevity and high performance of our machines, so you can work worry-free.

- Versatile and Safe: The Dura Series machines follow strict production and safety standards, making them suitable for workshops of all sizes.

With the Dura Series, you’re equipped to produce professional-grade products that can quickly turn a profit in today’s competitive market.

Acrylic is a preferred material for laser cutting due to its versatility and visual appeal. Whether clear, colored, or frosted, it offers endless possibilities for both functional and decorative products. Laser-cut acrylic boasts smooth edges and a polished finish that are difficult to achieve with other materials or methods.

Benefits include:

- Durability: Acrylic is resistant to weather, making it great for indoor and outdoor applications.

- Ease of Customization: With CO2 laser technology, you can easily adjust designs to create highly personalized products.

- Affordable Material: Acrylic sheets are relatively inexpensive compared to other materials, making them a cost-effective option for mass production.