How to Calibrate Your CO₂ Laser Machine for Precision Cutting

INDUSTRIAL NEWS

How to Calibrate Your CO₂ Laser Machine for Precision Cutting

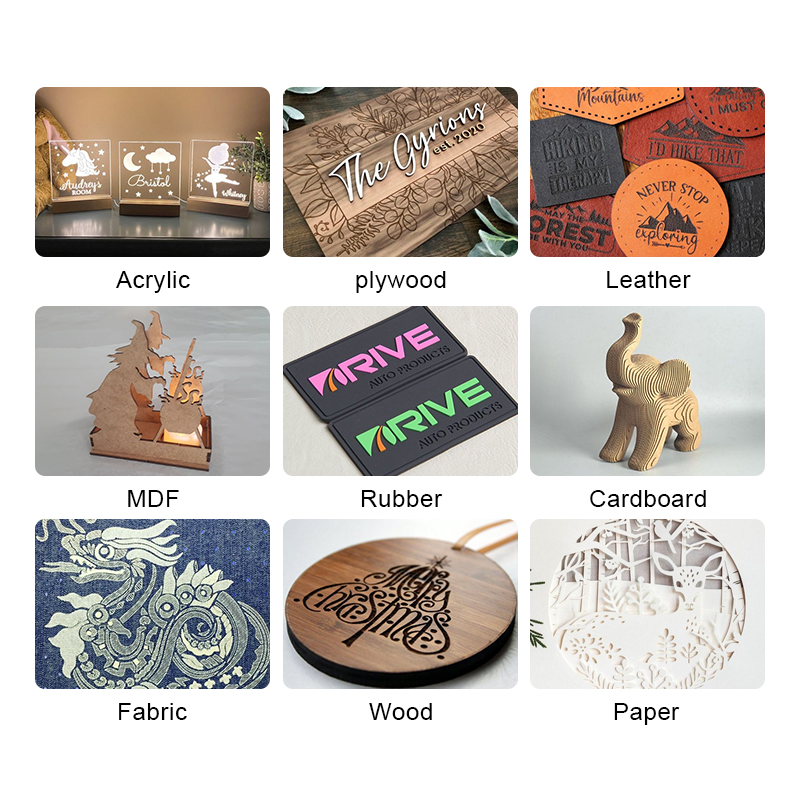

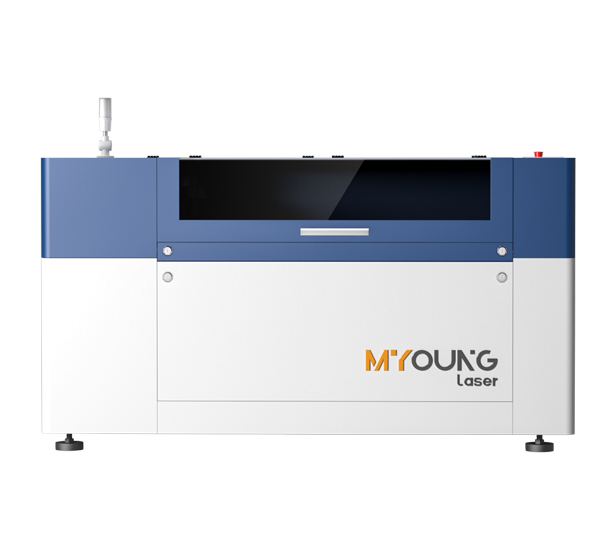

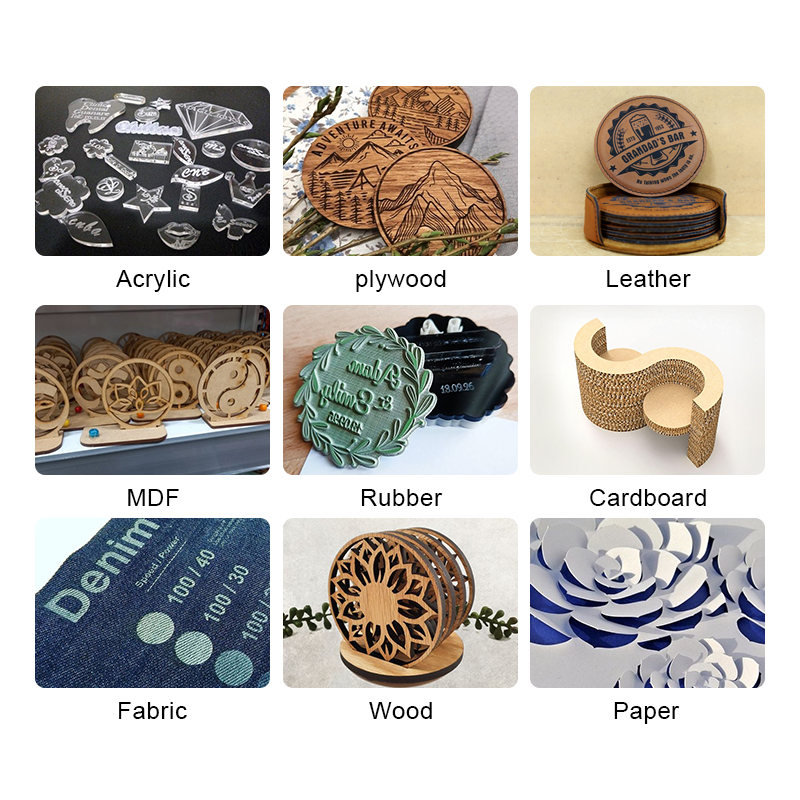

Precision is the heart of any effective CO₂ laser machine operation. Whether you’re cutting intricate acrylic patterns or engraving detailed artwork, calibration ensures that your cuts are clean, accurate, and consistent. Brands like MYounglaser, among leading CO2 laser machine suppliers, emphasize the importance of proper setup and regular calibration. This guide walks you through the essential steps to calibrate your machine for optimal performance.

1. Why Calibration Matters

A misaligned laser or improperly set focus can cause:

Burn marks on acrylic

Uneven cutting depth

Inaccurate engraving

Reduced machine lifespan

Proper calibration improves:

Cutting precision

Material efficiency

Repeatable results

2. Check the Laser Beam Alignment

Tools needed: Masking tape, alignment card, laser safety glasses.

Steps:

Place masking tape over each mirror (X, Y, Z axis).

Fire a low-power pulse to mark each position.

The marks should be centered—if not, adjust the mirror screws incrementally.

Repeat until the beam lands precisely in the same spot across the work area.

💡 Tip: Many CO2 laser machine suppliers, including MYounglaser, include alignment jigs with their machines.

3. Adjust the Focus Height

Why it matters: The focal point of your laser should match the thickness of the material you’re cutting.

Steps:

Use a focus tool (usually a calibrated spacer).

Lower or raise the laser head to match the exact focal distance (typically 2–5 mm for acrylic).

Lock the head in place once the proper focus is achieved.

Incorrect focus = wider kerf, charring, or failed cuts.

4. Calibrate the Stepper Motors (X/Y axis)

If your machine is misreporting position data, cuts may be distorted.

Steps:

Use a ruler and design a 100 mm x 100 mm square in your software.

Cut the square on acrylic and measure it.

If there’s deviation, adjust the steps/mm setting in your controller firmware or software.

Run the test again until measurements match the design.

5. Speed and Power Tuning

Different materials require different power and speed settings.

Steps:

Perform test cuts at various speed/power levels on scrap acrylic.

Look for:

Smooth edge (not burnt)

Full cut-through without chipping

Minimal discoloration

Save profiles for repeated use in your design software (e.g., LightBurn).

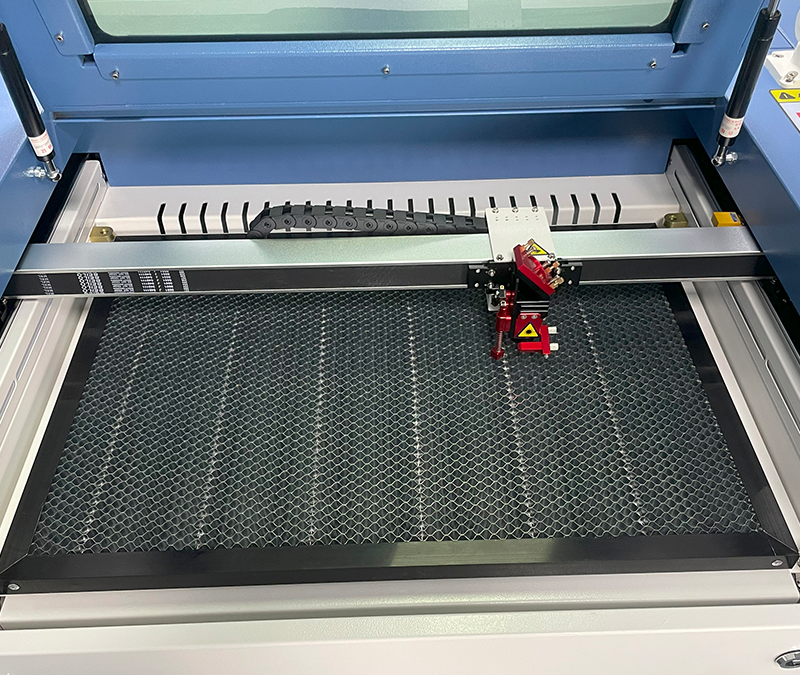

6. Bed Leveling

For even cuts across your work area, the laser bed must be perfectly level.

Steps:

Place a flat acrylic sheet on all four corners.

Measure the distance between the nozzle and material at each corner.

Adjust bed screws to match the lowest point.

Even 1 mm difference can affect cut quality.

7. Software Calibration Settings

Check settings like:

DPI (dots per inch)

Kerf compensation

Home position

Using the correct settings for your acrylic CO₂ laser cutting machine will eliminate software-based distortions or overlaps.

7. Layered Acrylic Light Fixtures

One of the most striking uses of laser-cut acrylic is in creating custom light fixtures. Layered acrylic pieces, cut into various shapes, are illuminated to produce beautiful, diffused lighting effects.

Why It’s Stunning: The laser cutting of acrylic enables artists to achieve unique shapes and patterns that create stunning visual effects when illuminated.

Laser Machine Used: MYounglaser CO2 laser cutters are designed to cut through thicker acrylic pieces, making them ideal for large-scale light fixture designs.

8. Intricate Laser-Cut Jewelry

Laser-cut acrylic is an innovative material for creating jewelry pieces that stand out. Whether it’s necklaces, earrings, or rings, laser cutting offers high precision, making complex patterns and designs possible.

Why It’s Stunning: The clean cuts and high-detail engraving provide a unique, artistic look that other materials may not be able to achieve.

Laser Machine Used: MYounglaser machines are perfect for cutting out detailed designs in acrylic, offering accuracy needed for jewelry production.

9. Custom Awards and Trophies

Laser-cut acrylic is commonly used for creating custom awards and trophies. Artists can design intricate and personalized shapes and engravings, making each award one of a kind.

Why It’s Stunning: The glossy finish of acrylic combined with precise engraving gives these awards a polished, professional appearance.

Laser Machine Used: CO2 laser machines from MYounglaser are perfect for engraving text and cutting out complex shapes, providing a high-quality finish.

10. Acrylic Planters and Terrariums

Laser-cut acrylic is also used to create stylish planters and terrariums, combining functionality with aesthetics. These can be customized with unique shapes and detailed designs, making them stand out as decorative pieces.

Why It’s Stunning: The transparent nature of acrylic enhances the visual appeal of plants while adding a modern touch to any space.

Laser Machine Used: MYounglaser offers precision cutting for smooth edges and accurate engraving on both thin and thick acrylic sheets.

Calibrating your CO₂ laser machine regularly ensures accurate, repeatable, and professional-quality results. Whether you’re a new user or a seasoned professional using a machine from MYounglaser or other CO2 laser machine suppliers, taking time to align optics, fine-tune focus, and level your work surface pays off with every cut.

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.