Getting Started with Acrylic Laser Cutting Machines

INDUSTRIAL NEWS

Getting Started with Acrylic Laser Cutting Machines

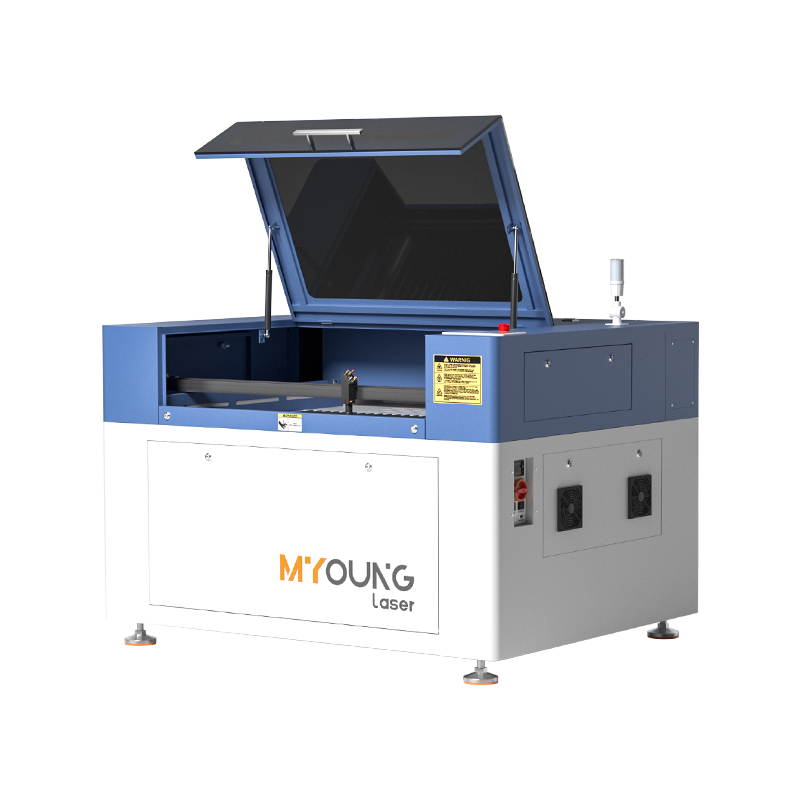

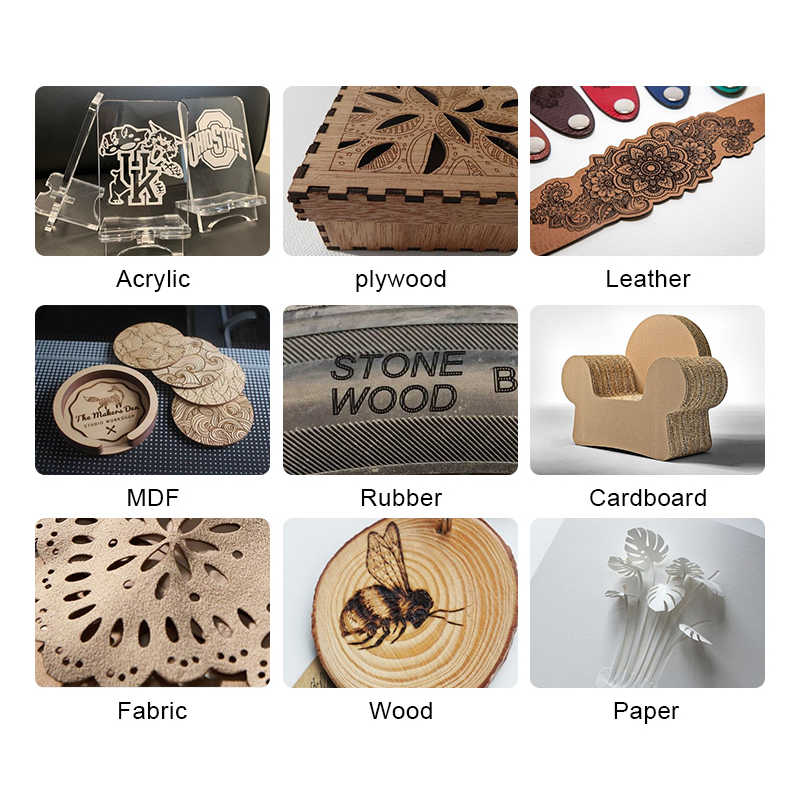

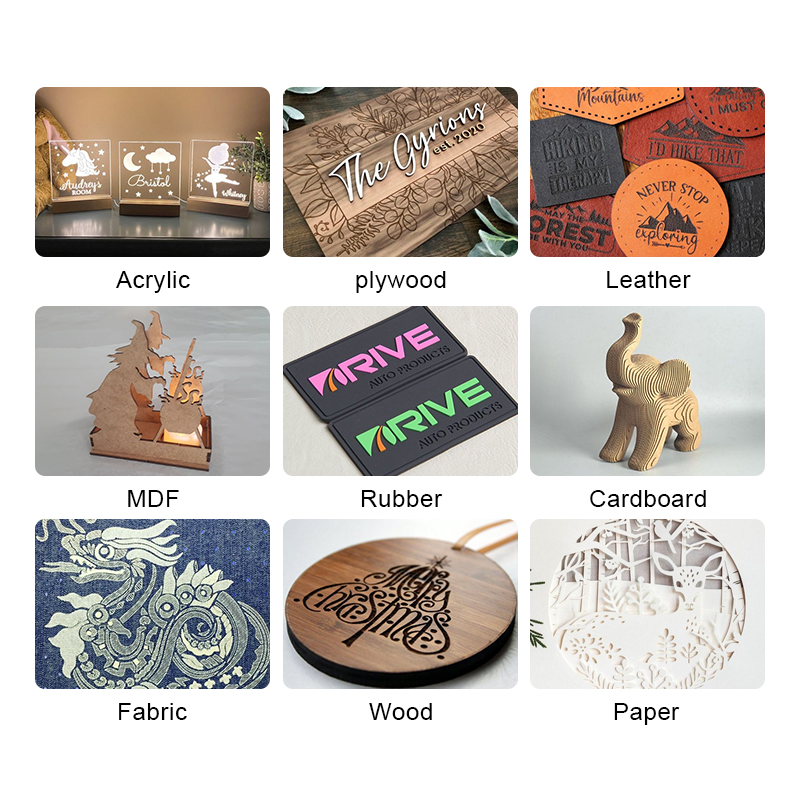

Acrylic laser cutting machines have revolutionized many industries, from signage and crafts to prototyping and production. If you’re looking to dive into the world of acrylic cutting using CO2 laser machines, it’s essential to understand the basics to get the best results. In this article, we’ll explore how to get started, what you need to know about working with acrylic, and why machines like those from MYounglaser are ideal for precision and efficiency.

1. Understanding CO2 Laser Machines

CO2 laser machines are one of the most versatile tools for cutting and engraving various materials, with acrylic being one of the top choices. These machines use a high-powered laser beam to cut through or engrave materials. The MYounglaser CO2 laser machines are known for their ability to handle complex acrylic cutting tasks efficiently, thanks to their high-speed performance and precision.

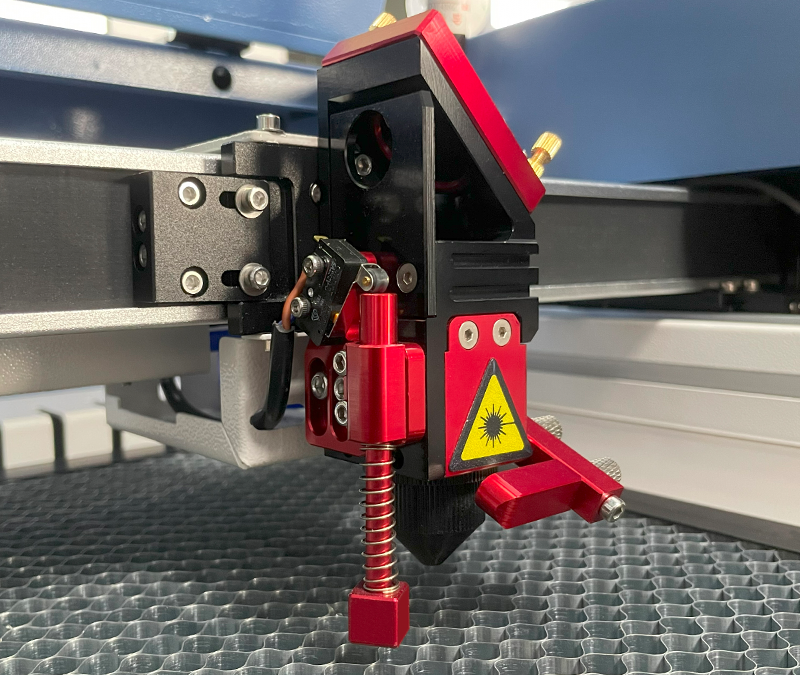

When working with acrylic, CO2 lasers are preferred because they produce clean, smooth cuts without the need for additional polishing. The machines work by focusing a high-energy beam on the surface of the acrylic, vaporizing the material along the cut path and leaving a glossy, polished edge.

2. Types of Acrylic for Laser Cutting

Before you begin cutting, it’s important to choose the right type of acrylic. There are two main types:

- Cast Acrylic: Ideal for engraving and cutting, as it produces a frosted, high-quality finish.

- Extruded Acrylic: This type is cheaper but may not give the same frosted finish when engraved. It’s more suited to simple cutting projects rather than engraving.

Depending on your project needs, cast acrylic is generally the better choice when you require fine details or intricate designs.

3. Setting Up Your Acrylic Cutting Project

When you’re ready to start cutting, preparation is key. Here are some factors to keep in mind:

Machine Settings: Different thicknesses of acrylic will require different laser settings. Thinner sheets (around 1-3mm) can be cut at lower power settings and higher speeds, while thicker acrylic (4-10mm) will need more power and slower speeds to ensure smooth cuts.

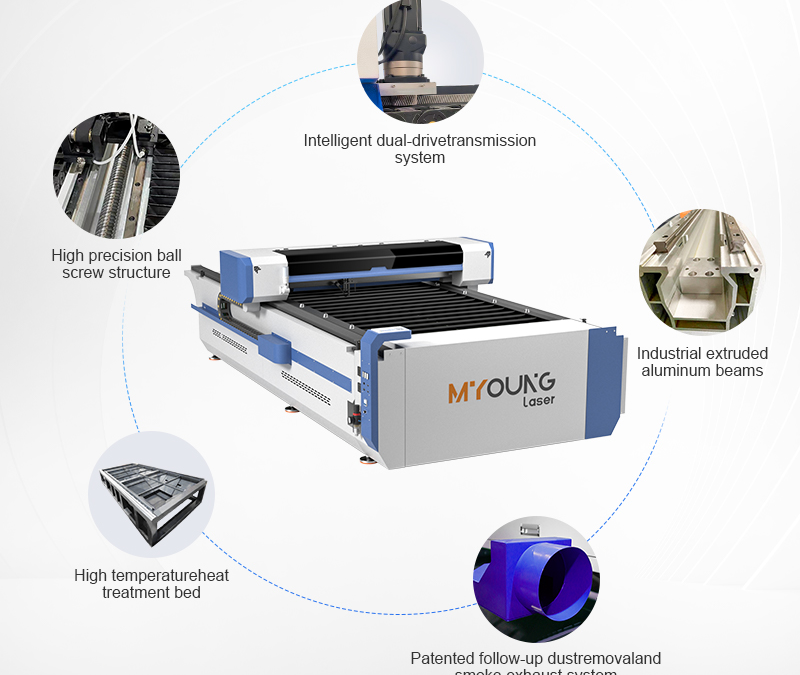

Air Assist: This feature helps blow away debris and cools the cutting area, which prevents burns or warping of the material. Machines like those from MYounglaser come with air-assist features that improve the quality of the cut.

Work Area: Always ensure the sheet size matches your laser’s work area. Machines such as the Dura 9 and Dura 13 offer spacious work areas (up to 1600x1000mm for larger projects).

4. Choosing the Right CO2 Laser Machine

When selecting a laser machine for acrylic, it’s important to consider the size and power that fits your needs. MYounglaser CO2 laser machines come in various models, each tailored for different project scales:

Dura 9: Great for small to medium-sized projects with a work area of 900x600mm and power ranging from 80W to 150W.

Dura 13: A versatile machine with a larger work area (1300x900mm) and up to 300W power, ideal for cutting thicker acrylic sheets.

Dura 16: For larger projects, the Dura 16 offers a 1600x1000mm work area, capable of handling thicker materials and high-volume production.

Each machine is equipped with features like high-torque Japan Shinano motors for precision, self-cleaning guide rails for smoother operation, and high-quality accessories to ensure long-term performance.

5. Designing Your First Project

Start simple! When you’re new to acrylic laser cutting, begin with basic shapes and designs. As you get more comfortable, you can move on to more intricate patterns or engravings. Software like CorelDRAW, AutoCAD, or Adobe Illustrator can be used to create your design files, which can then be imported into the machine’s control software.

6. Safety Tips

Working with laser machines requires a few safety precautions:

- Always wear protective eyewear designed for laser use.

- Ensure the laser machine is placed in a well-ventilated area or has a fume extractor, especially when cutting acrylic, as it releases fumes.

- Keep your workspace free of flammable materials.

Why Choose MYounglaser CO2 Laser Machines?

If you’re serious about acrylic laser cutting, the MYounglaser CO2 laser machines are an excellent choice. They offer powerful performance, precision, and durability, making them suitable for both beginners and professionals. Whether you’re working on craft projects, signage, or larger production runs, the Dura series provides the flexibility and reliability you need.

With features like Japan Shinano motors, air-assisted cutting, and customizable work areas, MYounglaser machines deliver top-notch results every time. Ready to start your acrylic laser cutting journey? Contact us today to find the perfect machine for your needs!